You must be of legal drinking age to enter this site

Don't worry. Your search results will include similar terms and products to make finding your products easier and quicker.

Our Fast Order feature is a great tool that collates your most popular items and makes it easier to order them again.

13 August 2021

Owning a successful IT company providing Ipad based Point of Sale Systems for the hospitality industry since the mid-noughties, Brennen and Brown founder and Managing Director Rich Bamber found himself turning his love of gin and ginger into a fast-growing business of its own.

In 2012, after being asked to install an Ipad till into a well-known distillery in London for their new bar, Rich asked the distiller if there was a gin with ginger as the predominant flavour. The distiller said there had been one, although that was over 100 years ago. Unfortunately, it no longer existed.

These words set Rich off on a path of amazing discovery.

After a lot of research, Una, a miniature & traditional Copper Still, was chosen. Copper as a metal has many positive characteristics that make it the preferred metal when making Stills. The copper reacts with alcohol on a molecular level making the final spirit taste better. With help from his partner Jo Hazlett, an already established Chocolatier, and with a bit of trial and error with quantities and flavours, Una produced Brennen and Browns first batch of Gin with a hint of Ginger.

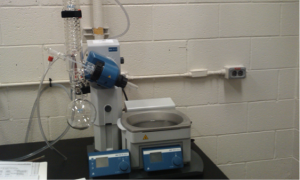

Our team was then introduced to Rotary Evaporator Stills. Soon to be our choice of Still, which is when ‘Gin-Of-Eve’ joined the team and production began in earnest.

Rotary Evaporator Stills allow for a gentle, precise and efficient distillation not found in conventional distilling equipment. Laboratory condensers, being sealed and made of glass, are easy to monitor and adjust visually. Keeping the mixture even and heated promotes stable and even evaporation concentrating the purest and freshest flavours. Thus, allowing Brennen and Browns Flavour Team to extract the aroma and flavour molecules from mixtures gently and at low temperatures, (e.g. extracting the desired flavours from a blend of alcohol, spices and fruit without heating the mixture), creating the tastiest, freshest and cleanest flavoured artisan Gins and Vodkas.

From the beginning, Brennen and Brown had lots of interest from local businesses, bars, night clubs and shops who like to support locals. The interest continued spreading further afield very quickly. Brennen and Brown found with the growing demand that we needed to produce 1000 bottles per week, and Gin-Of- Eve produced 3 bottles an hour. As demand grew, we decided to purchase two more rotary evaporators, Heidi, our Heidolph Rotary Evaporator and Flo-Mo, our Hydrion Scientific Rotary Evaporator, to meet the demands.

Gin-Of-Eve is our new product test rotary evaporator; we make small batches of new products to be tested by our dedicated team of tasters. Once the product has been approved, production moves on to Heidi or Flo-Mo, depending on how big a run we want to make. Rich now concentrates on the day to day running of the Brennen and Brown team, while Jo oversees the social media and the Flavour Nurseries, Team. Brennen and Brown make, bottle and label in-house, ensuring the best possible product reach our customers.

Why are we called Brennen and Brown? That bit was easy; they are Rich’s Grandmothers maiden names. Two lovely ladies that enjoyed the odd G&T themselves!